Work flow

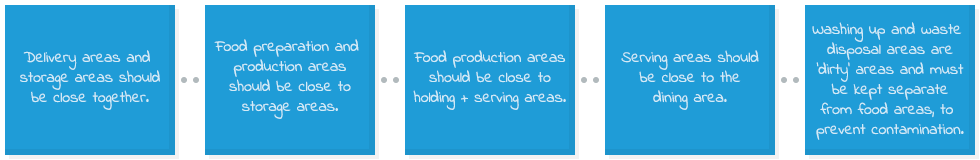

Regardless of the size of the kitchen, the layout and work flow should follow a logical process, incorporating the following stages:

- Delivery

- Storage

- Food preparation

- Cooking/food production

- Holding

- Food service

- Washing up

- Waste disposal

Think first

Can you think of any reasons why these principles are so important? What could the consequences be if these principles are not followed? For example, what would happen if delivery areas and storage areas were not close together? Or what if production areas and serving areas were a long way apart? Type your thoughts into the box below.

Setting up an effective work flow is all about minimising the movement of people and resources around the kitchen. The aim is to avoid back-tracking and crossover. This means making sure that materials, products and equipment are all within easy reach during every operational activity. Staff time is valuable, so the kitchen needs to be laid out in a way that reduces time wasted making unnecessary journeys.

An effective work flow will allow food to be moved through the kitchen, from the point of delivery and storage to the point of being sold or served to customers in the most easy and unobstructed way.

The various processes should be separated as far as possible – this can help to prevent contamination. For example, keeping raw ingredients separate from cooked ingredients, or keeping prepared food separate from waste food and other refuse.

Let’s consider some of the different working areas that make up the kitchen work flow. Click through the slide panel below to learn more.

-

Delivery and storage areas

The receiving area in a kitchen needs to be well designed to allow for easy access of vehicles and delivery of stock and supplies. There should also be enough space to allow for delivered goods to be checked before they pass into the kitchen.

Storage areas should be located near to the receiving areas, and also in a suitable position so that the stock and supplies can be distributed easily to the food preparation and production areas. The storage area needs to be large enough to store all of the supplies needed by the kitchen operation.

Food deliveries should have a separate entrance because of the risk of contamination. It is also a good idea to have a separate staff entrance to the kitchen.

-

Preparation areas

There can be many different preparation processes in a kitchen environment and each preparation process will require a different area (the facilities in each area will depend on the preparation task). For example, in a vegetable preparation area, lots of water will be used to clean the vegetables and dirt from the vegetables will build up – for this reason, this preparation area will need washing equipment and good drainage facilities.

The kitchen layout should ensure that there is enough workspace for each preparation process to take place safely, with all of the required equipment and utensils within easy reach.

Dirty and clean processes must be kept separate in order to avoid contamination. For example, vegetable preparation and washing up areas would typically be separate from areas where dishes are being prepared and served.

The layout must ensure a logical and linear workflow from one process to another, in one direction through the kitchen – for this reason, food preparation areas should be positioned between storage and cooking areas. This will avoid foods crossing over into areas that could present a risk of contamination (for example, raw ingredients crossing over into areas where cooked food is held). A logical layout will also prevent staff from having to move around the kitchen more than necessary – this makes their work more efficient and effective and staff don’t get in each other’s way.

Many preparation areas are also referred to as ‘wet areas’ – for example, fish preparation, vegetable preparation and butchery.

-

Cooking/production areas

Raw ingredients pass from the preparation areas into the cooking/production areas. The cooking/production areas will be designed to allow the ingredients to continue to flow through the process and out into the service area.

These areas will be planned to ensure that all of the necessary equipment is nearby so that dishes can be cooked quickly and effectively (for example, roasting ovens will be positioned near the meat preparation area, ready to receive meat for cooking and steamers may be positioned close to the vegetable preparation area and so on). A gas and/or electricity supply will be needed for the cooking equipment in these areas.

These areas will also be positioned near to the service area, so that final dishes can conveniently be passed through to service staff as soon as they are ready.

-

Holding and service areas

The holding area is where food is held, prior to being served to or purchased by customers. This area needs to be close to the service area, for quick and effective service to customers.

If hot food is held, it must be done so at a temperature of over 63°C. Cold food may be held in chillers or refrigerated cabinets.

Food service areas must be located near the cooking/production areas, so that final dishes are quickly and easily made available for service to customers.

-

Cleaning areas

Food safety must always be a high priority in any kitchen layout. For example:

- There should be enough space to allow for access to all kitchen equipment so that it can be cleaned thoroughly

- There should be designated space for all used equipment/utensils from the dining area to be cleared, cleaned and stored

- Suitable handwashing facilities for staff must be provided

- There needs to be a separate area for washing up (pots, pans, plates, etc) – this area will need to have enough space for the required cleaning equipment, such as sinks, dishwashers, pot wash machines, etc

- Rubbish must be kept in a suitable area, well away from the preparation and production areas (and rubbish must not pass through these areas to reach its storage space)

Key point

As you can see, an effective kitchen work flow can help to achieve:

- Good communication between staff

- Improved efficiency (everything happens more easily and effectively)

- High-quality finished products, served to customers in a timely manner

- A safe working environment

- High levels of food safety